Roller Bearings Are So Much Better: Here's Why.

By definition, a roller bearing is used to support both radial and axial loads of the main shaft, axles, or wheels. They are low on friction and high precision.

Roller bearings are convenient to use in machines because they have accurate self-alignment, therefore, they can control issues in mounting and misalignment. With that being said, using this type of bearing can cut off labor costs, maintenance, and repair.

Generally, using this is cost-effective and low maintenance. Because the wear and friction of a roller bearing are low, it does not require a high quantity of grease or lubricant, making its service life longer.

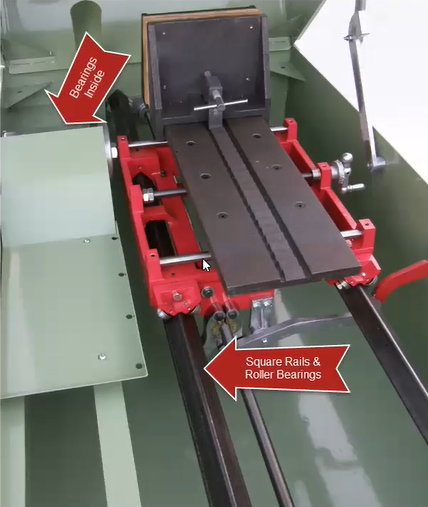

In Highland Park saws, we use roller bearings on our carriage, compared to other saws which use round rails. Although it costs more, roller bearing is better because of the actual design of the rails it runs on.

Because of the rail structure (see photo below), the sediment that's being produced when cutting won't get stuck on the rails. The rails allow the roller bearings to roll on smoothly and as a result, give precise cuts on the material.

The design of the rail never wears out. A roller bearing may wear out over time and has to be replaced, but the rail it stands on will remain sturdy.

Saws that have carriages riding on round rails tend to wear out faster. The reason for this is: when you cut material, the dust or grit will spread onto the round rails. When the carriage runs through the rails, the sediment will rub onto the metal carriage, causing the carriage to wear out faster.

We prevented that instance from happening by modifying our rails and adding roller bearings. Based on the photo above, with a square structural steel rail, the sediment will slide off, leaving the rails clean, and will expand the life of the carriage immensely.

To sum it up, roller bearings are a crucial contribution to your saw's sturdiness. With the smooth rolling of the carriage, the cuts produced are precise and smooth. It is essential to hold the workpiece against the blade with firm, steady pressure.