Tumbling 101: 10 things you need to know before rock tumbling

Tumbled rock is one of the most common things we see in physical stores or on Etsy, Amazon, or eBay. It's similar to what we see on the beach shore – those smooth rounded rocks tumbled naturally for years.

You can recreate those stones in weeks with just a machine and a few materials. Rock tumbling is the process of creating shiny and rounded stones using a specific machine called a rock tumbler.

There are two types of tumblers: rotary and vibratory.

A rotary tumbler has a spinning barrel and is more common in the market. It produces rounder stones and it is usually what beginners opt for because it's cheaper, quieter, but it takes a longer time to tumble.

Vibratory tumblers are mostly used by professionals as a second step after using the rotary tumbler for more professional results. Unlike rotary tumblers, vibratory tumbler keeps the original shapes and angles of the stone; it just gives a polished look.

Every lapidarists has their own way of tumbling. What might work for others may not work for everyone. Here are some general tips for rock tumbling:

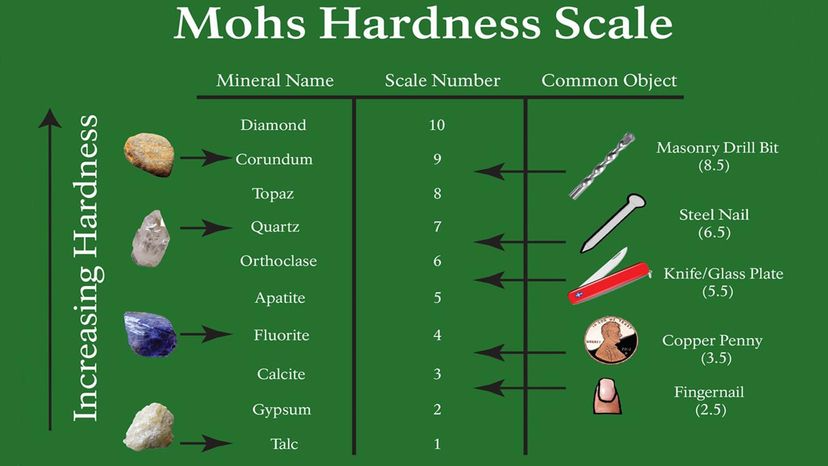

1. Tumble rock that have similar hardness. When you work with random rock without taking their level of hardness into account, you'll do more harm to your stones than actually making them look good. You can use the Mohs Hardness Scale by National Park Service below as a guide.

This scale indicates the scratch resistance (hardness) of a rock. In tumbling, level 7 rock is the safest you can tumble, which is quartz. Tough rocks like diamonds are difficult to tumble, especially for a beginner. The same goes with a softer rock, such as fluorite which can be scratched by a copper penny. Soft rock will just crack or worse, disintegrate inside the barrel.

Make sure that each batch of rock is segregated according to their hardness. This is crucial in tumbling. If you mix soft and hard rock, the harder ones will scratch the other stones, ruining the finish of the stone.

2. Don't tumble cracked rock, extremely porous, or fractured stone. There's a saying in the rock tumbling world that goes, "trash in, trash out" which means that if you put ugly rock inside a barrel, don't expect it to look magically good after tumbling. You'll waste your time and supplies trying to make them look good, but tumbling won't do much for them.

Rock tumbling takes weeks, sometimes months, so it's better to choose good quality rock to produce higher quality tumbled stones. Moreover, thin rock must be discarded too as they have a high risk of breaking and will just damage the rest of the batch.

3. Don't overload your barrel! This is very important, as your stones won't tumble properly if they're jammed inside the barrel. The amount of rock you need to put varies in the size of the barrel. Most of the time, manufacturers provide a guide of how much a barrel should be filled. But don't fill it 3/4 full, it will take too long to achieve your desired results. Instead, fill it until it's 2/3 full. If your rock's quantity can't reach that amount, use fillers like ceramic media.

4. You can use different sizes of rock in a single batch. Although different hardness is forbidden, you can totally mix a variety of sizes in a single batch, as long as it's not too big or too small. Good tumbled rock comes from a variety of sizes because as the rocks grind against each other, it encourages the tumbling process, which is better.

5. Use a good quality grit and polishing powder. Not all grit sold in the market are the same. If the grit is too cheap, chances are its poor quality. Invest in some good quality grit like silicon carbide. It will increase the success rate of your tumbled rock. For polishing powders, some of the best to use are tin oxides, cerium oxides, and aluminum oxides.

6. Stock up on good ceramic and plastic media. If your rock doesn't fill the load, ceramic and plastic media can be useful. Ceramic media provides good cushioning for your rock. It's better to have them in different sizes as well.

However, you can only use fresh ceramic media (ones with rough edges) during coarse grinding. Using rough ceramic in the polishing stage will scratch your rock, so be sure to use only the smooth ones. To smooth the rough edges, you can run the ceramic along with your other rock in stage 1 or coarse grind, or you can pre-tumble them alone twice for a couple of hours.

But if you're a bit skeptical whether to use them in a polish, it's better to use plastic media, as it's much softer than ceramic. So to sum it up, use ceramic media during the coarse grind stage, and plastic pellets for the polishing stage.

Ceramic media from rocktumbler.com Plastic pellets from aussiesapphire.com.au

7. Wash your rock and tumbler thoroughly in between stages. Having leftover grit from the previous stage is not a pleasant scenario. It will scratch your rock and then you'll have to go through the trouble of running them again in the previous stage. It's better to rinse your rock with ivory soap or borax before you run them in a new stage.

There are times where grit gets stuck inside a rock fracture and it will be too hard to remove no matter how you scrub it. If this happens, don't include that rock in the next stage. This is because the grit may escape the fracture while tumbling, and it will ruin the rest of the batch. You don't have to throw it out, instead you can tumble the rock again with your second batch, going to the same stage it went through before.

Some people recommend using different tumblers for polishing and coarse grinding, as it is a little tricky to clean out barrels. However, using a single tumbler throughout different stages is fine, as long as you make sure no grit is left when going through each stage. You can use a toothbrush for easier cleaning. It's also better to wash your barrel immediately after using it, rather than waiting for the next day because then you'll have a hard time scrubbing off the hardened slurry.

8. You don't have to throw away your slurry immediately. You can reuse them if you're running a different batch on the same stage. The same goes if you are going to re-run a batch. Just add more grit or water if needed. You don't have to consume your grit that fast when it can be recycled. If your slurry gets too muddy though, then it's time to discard it.

9. Don't drain your slurry directly onto your sink – it will clog up your pipes! Use your classic kitchen colander and bucket in washing your rock to prevent the grit from draining into your sink.

10. Patience, patience, and patience. Since the machine does most of the work, all you have to do is check it from time to time and wait. It's not a secret that tumbling takes a long time. For some material it takes 2 to 3 months to finish a single batch. Just make sure to follow the procedure of your tumbler and use high quality grits and polishing powders so as not to let the time – and electricity – go to waste.

Don't be afraid to experiment, though. Try new polishes, grits, or you can try other techniques until you find the one that gives you the best results. Just keep in mind the basic rules like batching rock with similar hardness and discarding physically unqualified rock.

If you don't get the results you're expecting, don't be discouraged. You can always rerun the tumblers again. You'll eventually master tumbling the more you do it.